The built-in code editor features syntax highlighting, line numbering, auto completion and reformatting, allowing you to customize the font style and the coding colors for both the text editor and the debugging window for break and execution points. The main window comprises options for controlling the simulation playback, enabling you to start, pause or stop the procedure, as well as jump forward to a new step. The debugging mode allows you to identify execution errors in your code. The currently active command is highlighted, so that you can easily find any error that might occur and the operation parameters can be viewed in the main window. Alternatively, you can preview the result of the CNC program in 3D using the OpenGL technology.

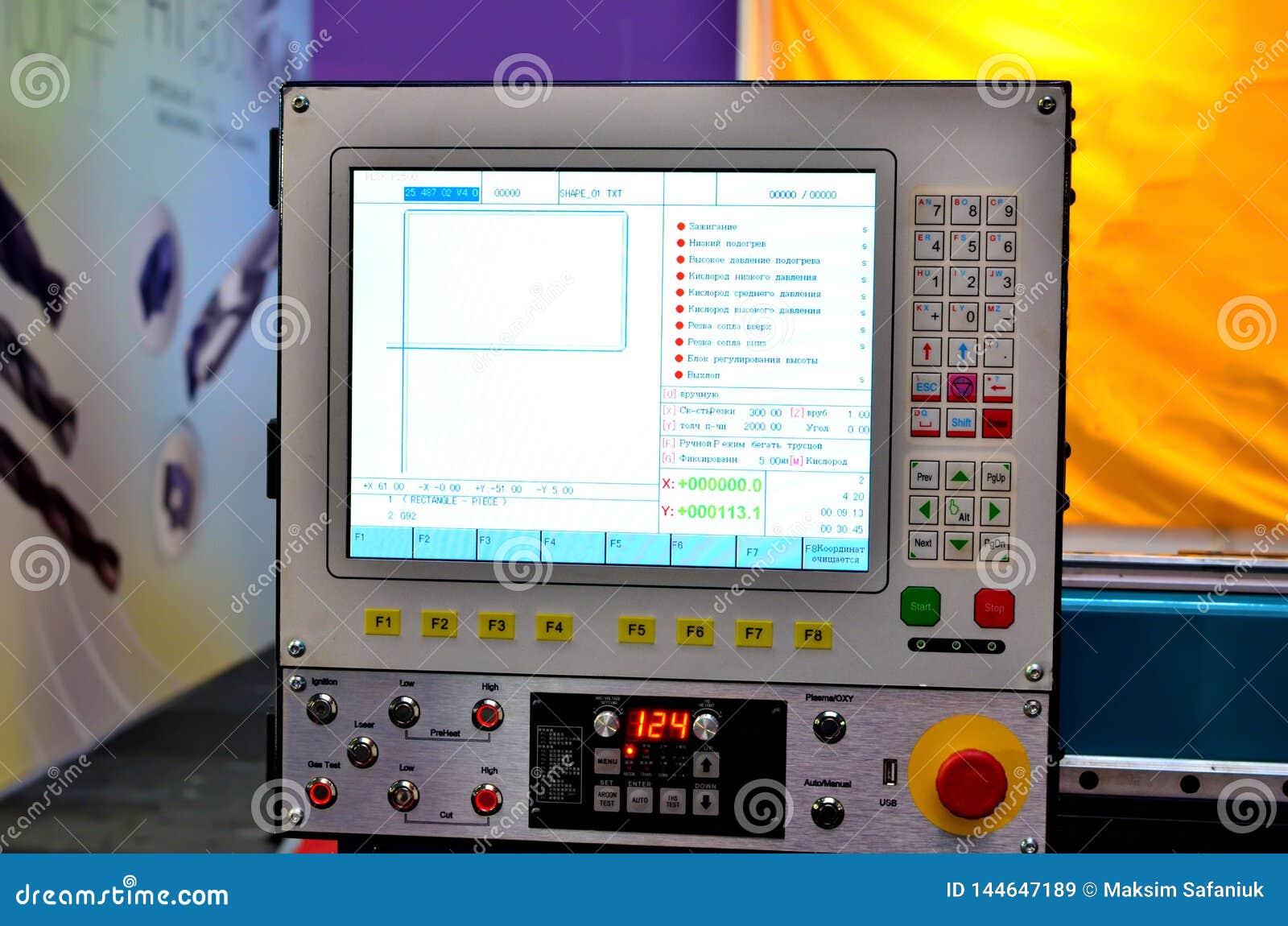

The 2D simulation enables you to view the path that the CNC lathe machine follows as the instructions are executed one by one. The application features an intuitive interface, comprising two separate panes, one for writing the g-code and the other for previewing the result. It is designed to assist machinists in learning about g-code writing and CNC programming, while also providing them with a way to test their instructions and commands. This is what makes the checking and correction of toolpaths before NC output so reliable: The completeness of the libraries and the high degree of detail of the digital twins.CNC Simulator is a comprehensive utility that enables you to simulate a Computer Numerical Control (CNC) machine. And of course, zero-point clamping systems and units such as jaw chucks, study rests and tailstocks are fully accounted for. We create and approve postprocessors and virtual machine models.Īll tool assemblies can be represented with absolute precision in the tool library, including HPC cutters and circle-segment cutters with all holders.

We digitize your individual adaptations directly on site. The entire range of common machine controls and common machine types are supported: This also includes complex multi-axis machines and multi-function machines, including turning/milling machines, lathes with main and secondary spindles, deep drilling machines and robots with additional axes. All of the components in your special manufacturing environment can be realistically stored in virtual process libraries in Tebis. The machine library includes over 1,400 virtual machine models from different manufacturers in 3,700 variants.

0 kommentar(er)

0 kommentar(er)